Digital Twin Monitoring System

Production Equipment Management:Equipment operation status, abnormal alarm, maintenance and other life cycle of delicacy management

Order Comprehensive Analysis:Production order visualization and tracking, business and product data analysis, production strategy adjustment

Production Line Visualization:Key process monitoring, production quality control

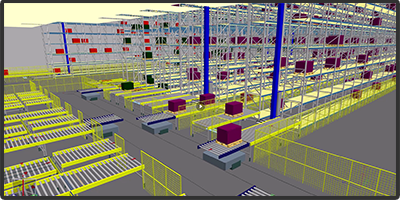

Material Storage Management:3D model data analysis and visualization, intelligent inventory, inventory alert, improved inventory accuracy

Energy System Management:Real-time data access of plant energy consumption, electricity and gas usage data analysis, equipment energy consumption optimization